Tallahassee Silica Free Quartz Countertops News

Understanding Bioquartz®: The Revolutionary Silica-Free Alternative

Bioquartz® represents a groundbreaking innovation in engineered stone technology that completely eliminates crystalline silica while maintaining the performance and aesthetics of traditional quartz. Developed by Breton through a "pyrolytic transformation" process that involves melting common siliceous and feldspar sands at approximately 1800°C, this material converts any crystalline silica into amorphous (non-crystalline) forms. The result is a 100% silica-free material that offers the same hardness (around 7 on the Mohs scale), scratch resistance, and visual appeal as traditional quartz, while eliminating the health risks associated with silica dust exposure during fabrication.

Silica-Free vs. Low-Silica Countertops

The countertop industry has responded to the silicosis health crisis by developing two categories of safer alternatives: low-silica and silica-free options, though there's significant confusion due to inconsistent industry definitions. Traditional engineered quartz contains 90-97% crystalline silica, while "low silica" products can range from less than 1% to below 40% depending on the manufacturer, with no standardized industry definition.

The Health Benefits of Silica-Free Countertops

Silica-free countertops offer crucial health benefits by eliminating the risk of silicosis for fabrication workers, while also providing peace of mind for homeowners concerned about ethical consumption. Traditional engineered quartz contains 90-97% crystalline silica, significantly higher than natural stones like granite (20-60%) or marble (less than 10%), and when processed, releases dangerous dust that can cause silicosis, an incurable and potentially fatal lung disease.

How Does Silica-Free Quartz Compare Against Engineered Quartz?

Silica-free engineered stone alternatives generally perform on par with traditional quartz in most respects, with some offering specific advantages in areas like impact resistance and aesthetic consistency. High-quality silica-free engineered stones like Bioquartz® maintain hardness ratings around 7 on the Mohs scale and may actually outperform traditional quartz in edge strength and impact resistance due to their more uniform internal structure.

BioQuartz® vs. Traditional Quartz

BioQuartz® represents a fundamental shift in engineered stone manufacturing that maintains all the desirable characteristics of traditional quartz while completely eliminating health risks through its revolutionary production process. Unlike traditional quartz which contains up to 93% crystalline silica, BioQuartz® is produced through pyrolytic transformation of common siliceous and feldspar sands at approximately 1800°C, resulting in a material that's 100% free of crystalline silica.

Tallahassee Eco-Friendly Kitchen Countertop Options: Beyond Granite and Quartz

The countertop industry is undergoing a transformation driven by health concerns over traditional engineered quartz's high silica content (90-93%) and growing demand for environmentally responsible materials. Traditional engineered stone contains significantly higher crystalline silica than natural stones like granite (20-60%) or marble (often less than 10%), creating serious health risks for fabrication workers through respirable dust that causes silicosis.

The History of BioQuartz®

BioQuartz® is a revolutionary silica-free industrial aggregate developed by Breton S.p.A. and officially trademarked on April 13, 2018, representing the most significant advancement in engineered stone technology in decades. The material is produced through pyrolytic transformation of common siliceous and feldspar natural sands at temperatures around 1800°C, which fundamentally changes the structure to eliminate crystalline silica while maintaining the technical and aesthetic characteristics of natural quartz.

Tallahassee Households Find Silica-Free Quartz Countertops Are Changing Their Choices

The countertop industry is experiencing a revolutionary transformation as silica-free alternatives address the serious health crisis caused by traditional engineered quartz, which contains up to 93% crystalline silica and has led to numerous silicosis cases among fabrication workers. This health emergency has prompted regulatory responses including Australia's ban on engineered stone and California's emergency safety standards, while driving innovation in safer alternatives like Bioquartz®.

How Low Silica Engineered Stone is Transforming Tallahassee Kitchens

Low silica engineered stone represents the industry's response to the silicosis health crisis, offering significantly reduced crystalline silica content compared to traditional formulations that contain 90-93% silica, though the term "low silica" lacks standardized definition across manufacturers. Different manufacturers use varying thresholds to define "low silica," with levels ranging from less than 1% (Cosentino Q0, Caesarstone CSF) to less than 40% (broader Silestone Hybriq+ range), creating confusion for consumers.

Zero Silica Countertop Options: Beauty with No Compromise

Zero silica countertops eliminate the health risks associated with traditional engineered quartz while maintaining superior performance and aesthetics, with Chromia Plus with Bioquartz® leading this revolutionary category. Traditional engineered quartz contains up to 90% crystalline silica, which releases dangerous respirable dust during fabrication that can cause silicosis, an incurable and potentially fatal lung disease affecting workers.

Safe Quartz Alternatives for Tallahassee Kitchen Countertops

The countertop industry is transforming away from traditional engineered stone toward safer alternatives that eliminate crystalline silica health hazards, with multiple categories of silica-free materials now available to meet diverse consumer needs. Traditional engineered quartz contains over 90% crystalline silica, creating serious health risks for fabrication workers through respirable dust that causes silicosis, prompting regulatory actions including Australia's nationwide ban and California's emergency standards.

What is Low Silica Quartz? The Complete Guide

Low silica quartz represents the industry's response to the silicosis health crisis, but the lack of standardized definitions creates consumer confusion as manufacturers use wildly different thresholds ranging from less than 1% to less than 40% crystalline silica content. Traditional engineered quartz contains 90-93% crystalline silica, significantly higher than natural stones, and fabrication creates respirable dust that causes silicosis in workers, sometimes after just 10-15 years of exposure.

Aurea Stone ZERO vs BioQuartz®: Which Silica-Free Countertop Technology Wins?

Two revolutionary silica-free technologies have emerged to address the countertop industry's health crisis: Aurea Stone ZERO and BioQuartz®, both offering zero crystalline silica content while taking distinctly different approaches to innovation and manufacturing. Aurea Stone ZERO focuses on creating premium surfaces with hyperrealistic printed patterns mimicking natural stone, using recycled components and advanced resins while claiming the lowest carbon footprint in the market.

Low Silica Quartz vs Silica Free Quartz Countertops

The countertop industry offers two distinct categories of safer alternatives to traditional high-silica quartz: low silica options (containing significantly reduced but not eliminated crystalline silica) and completely silica-free alternatives that contain 0% crystalline silica. Low silica products from manufacturers like Cosentino (Silestone XM with maximum 10% silica) and Caesarstone (Mineral line with varying silica levels) offer significantly improved safety over traditional quartz that contains up to 93% crystalline silica.

What is a Silica Free Quartz Alternative?

What is a Silica Free Quartz Alternative?

BioQuartz® represents the most significant advancement in countertop technology in over 50 years, offering a complete reinvention of engineered stone that delivers identical performance to traditional quartz while achieving zero crystalline silica content. Developed by Breton S.p.A. through pyrolytic fusion technology that melts common sands at 1500°C, BioQuartz® transforms crystalline structures into amorphous forms, creating a synthetic aggregate that eliminates the health risks responsible for 294 confirmed silicosis cases in California alone.

Which Silica-Free Quartz Countertops are Eco-Friendly?

The evolution toward silica-free countertops has created a new generation of environmentally responsible surfaces that address both worker safety and sustainability concerns, with leading manufacturers implementing comprehensive eco-friendly practices. Cosentino's Hybriq+ technology reduces silica content while incorporating minimum 20% recycled materials and achieving 100% renewable electricity usage with 99% water recycling, while Caesarstone's Mineral collection replaces crystalline quartz with alternative minerals and recycled materials.

BioQuartz®: A Safer and More Sustainable Alternative to Quartz

What is Bioquartz®?

Bioquartz® is an innovative industrial material that is 100% free of crystalline silica. It is produced by subjecting regular siliceous and feldspar sands, or remnants from the slab manufacturing process, to a pyrolytic transformation, which involves melting these materials at approximately 1500°C. This process creates a material that possesses the same technical and aesthetic features as quartz, making it an ideal substitute in the production of engineered stone slabs [3].One of the key advantages of Bioquartz® is its safety profile.

Crystalline silica, a common component of natural quartz, is a known carcinogen that poses significant health risks to workers involved in the fabrication of quartz surfaces [5]. By eliminating crystalline silica, Bioquartz® provides a safer work environment and reduces the risk of silicosis and other respiratory illnesses[2]. Furthermore, there is a growing policy focus on restricting the trade of products with high crystalline silica content [4]. Bioquartz® offers a solution to comply with these regulations and provides a responsible alternative for manufacturers and consumers concerned about the health and environmental impacts of crystalline silica.

Technological Applications of Bioquartz®

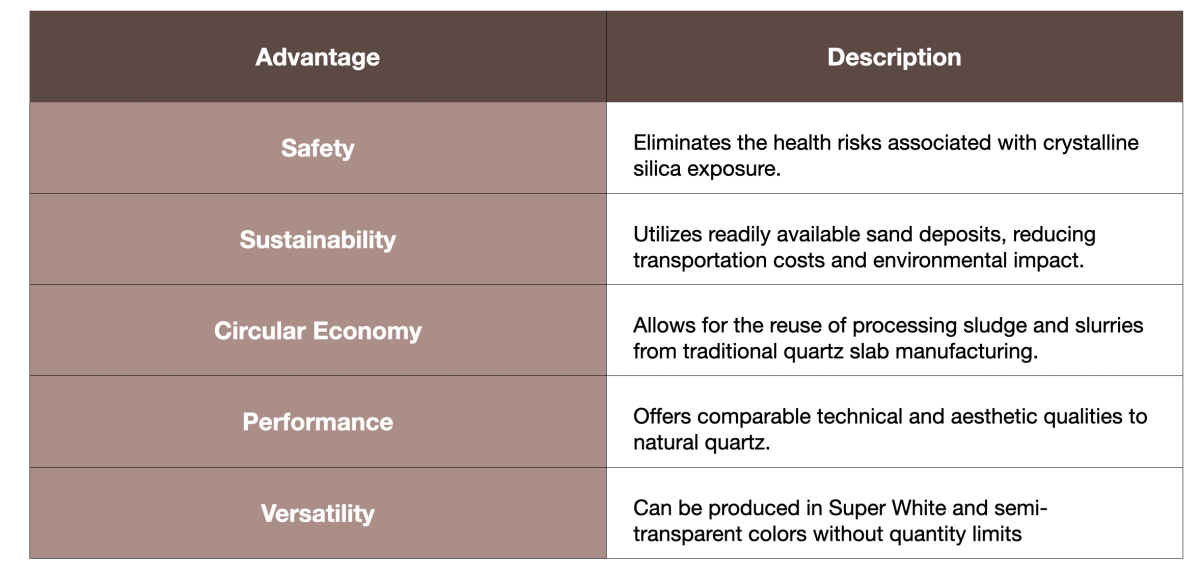

The primary application of Bioquartz® is in the manufacturing of engineered stone slabs. These slabs are widely used in countertops, flooring, wall cladding, and other applications in the construction and interior design industries [2]. Bioquartz® can be used as a direct replacement for quartz in the production process, offering several advantages, which are summarized in the table below:

Advantages of Bioquartz®

In addition to the advantages outlined above, Bioquartz® offers several specific benefits over traditional quartz:

- Enhanced Health and Safety: Bioquartz® is completely free of crystalline silica, eliminating the risk of silicosis and other respiratory illnesses associated with quartz dust exposure. This makes it a safer choice for workers and contributes to a healthier work environment [6].

- Improved Sustainability: Bioquartz® is produced using readily available sand deposits, reducing the need to quarry and transport large quantities of quartz. This reduces transportation costs, minimizes environmental impact, and supports sustainable sourcing practices [6].

- Compatibility with Existing Processes: Bioquartz® can be seamlessly integrated into existing vacuum vibro-compression production processes, making it a convenient and cost-effective alternative for manufacturers [6].

History of Bioquartz® Development

Breton S.p.A., a leading manufacturer of stone processing machinery and technology, has been at the forefront of developing innovative and sustainable solutions for the industry [2]. Over the past decade, Breton and its Institute of Technology (BIT) have prioritized operator safety and waste reduction as strategic goals, leading to the development of Bioquartz®6. This commitment arose in response to the growing concerns surrounding the health risks associated with crystalline silica [4]. Breton has invested significant resources in research and development to create a viable alternative to quartz. They have designed and installed a state-of-the-art industrial plant for the production of Bioquartz®, enabling customers to conduct industrial trials and produce silica-free surfaces [2].

Scientific Research on Bioquartz®

While there is limited scientific research specifically focused on Bioquartz® as a manufactured material, there are studies that explore the formation of quartz in natural settings. For example, research has investigated the precipitation of biogenic quartz (bioquartz) from pore waters that have become supersaturated due to the dissolution of biogenic opal [9]. This research, while not directly related to the industrial production of Bioquartz®, provides valuable insights into the properties and behavior of quartz in different environments.

Environmental Impact of Bioquartz®

Bioquartz® offers several environmental benefits compared to traditional quartz:

- Reduced Transportation: The use of readily available sand deposits reduces the need to transport ground quartz from distant quarries, minimizing transportation costs and associated pollution. This also contributes to a lower carbon footprint and reduced reliance on fossil fuels [2].

- Waste Reduction: The production process allows for the reuse of processing residues from traditional quartz slab manufacturing, contributing to a circular economy and minimizing waste. This reduces the need for landfill space and promotes resource efficiency [7].

- Elimination of Crystalline Silica Dust: Bioquartz® eliminates the generation of crystalline silica dust during the fabrication process, reducing the environmental impact associated with this hazardous material. This protects both workers and the environment from potential harm [5].

Future Developments and Applications

Bioquartz® is a relatively new material, but it has the potential to significantly impact the engineered stone industry and beyond. Future developments may include:

- Wider Adoption: As awareness of the health risks of crystalline silica grows and regulations become stricter, the demand for Bioquartz® is expected to increase, leading to wider adoption in the construction and design sectors.

- New Applications: The unique properties of Bioquartz® may lead to its use in other applications beyond engineered stone, such as ceramics, glass, and other industrial materials. This could further expand the market for Bioquartz® and contribute to its overall sustainability.

- Enhanced Sustainability: Further research and development may focus on optimizing the production process to further reduce the environmental impact of Bioquartz®. This could involve exploring new energy sources, minimizing water consumption, and improving waste management practices.

Bioquartz® represents a significant advancement in the engineered stone industry. By eliminating crystalline silica, it offers a safer and more sustainable alternative to traditional quartz. With its comparable technical and aesthetic qualities, Bioquartz® is poised to become the material of choice for manufacturers and consumers seeking to prioritize health, safety, and environmental responsibility.